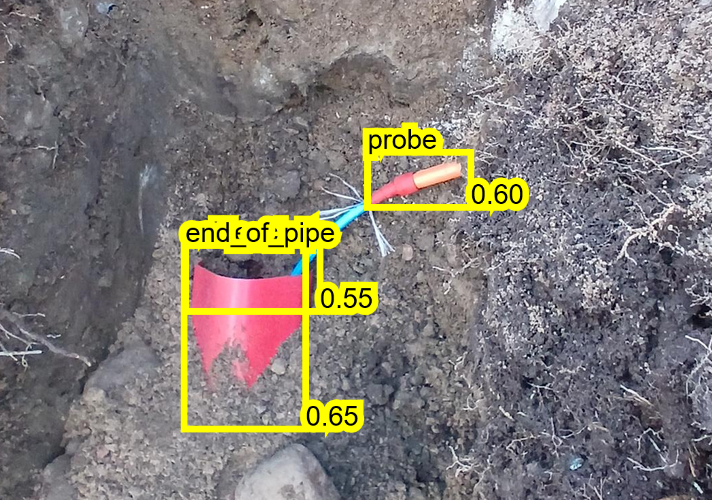

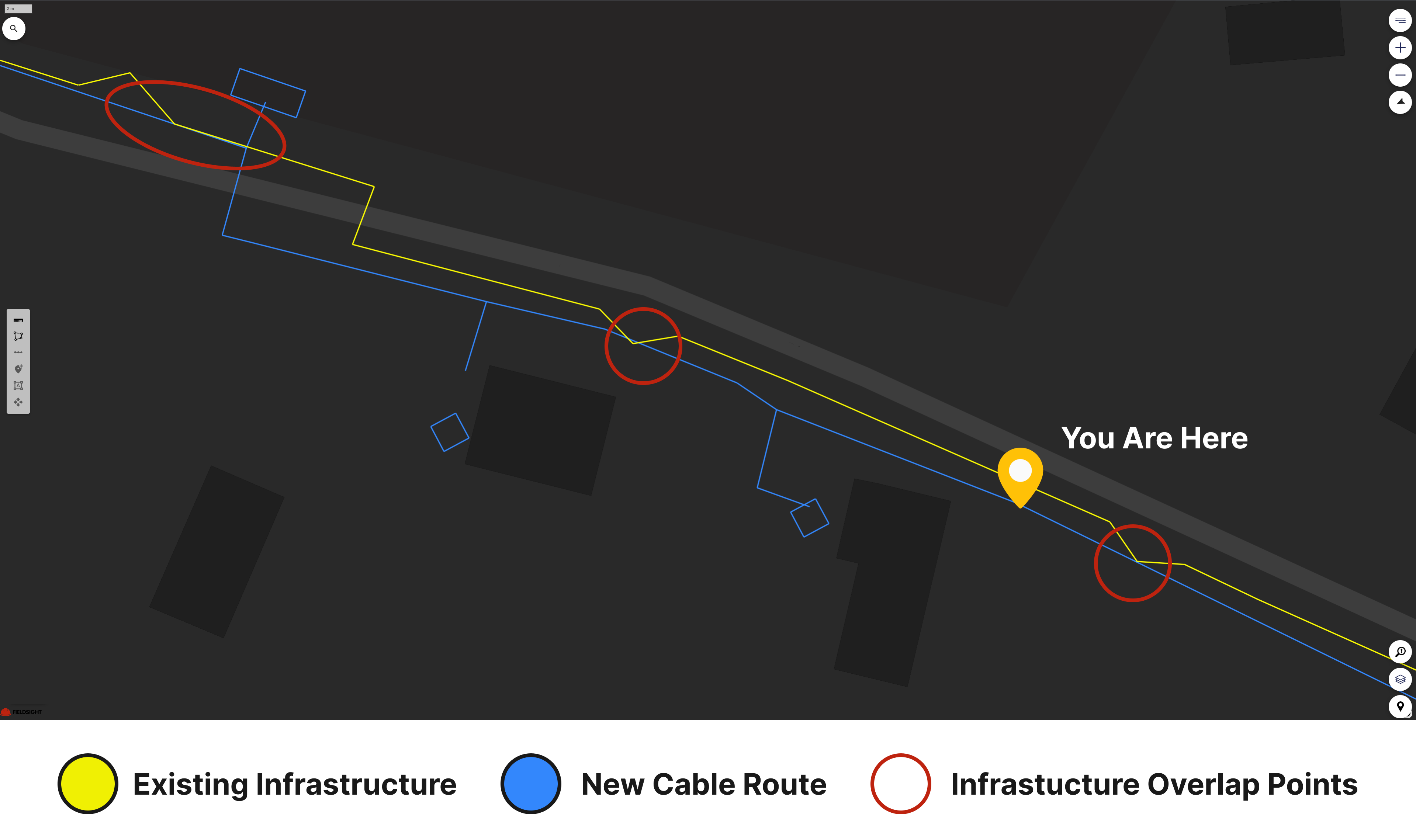

In the construction industry, the stakes are high when it comes to accidental cable cuts. Repairing a damaged fiber optic cable can lead to significant expenses, not just from the immediate repair costs but also from a range of associated financial burdens. For many construction firms, accidental cuts are not rare events. The financial implications can be extensive, encompassing: In the Netherlands, network operators are required to report all incidents of damage to their infrastructure. According to the Kadaster’s annual report on underground utility damage, there were 41,169 incidents of annual excavation damage in 2018, resulting in direct costs of €34,500,000. The average repair cost per excavation damage incident was approximately €838. Furthermore, if these direct costs are multiplied by a factor of 29 (based on UK research), the total cost of underground utility damage to the Dutch economy is estimated at about €1 billion annually. This highlights a significant financial burden, as research indicates that underground utility damage represents a major drag on national economies, amounting to $50 to $100 billion annually in the U.S., £ billions in the U.K., and €1 billion in the Netherlands. In recent cases, some cables were installed at insufficient depths, leading to additional rework costs. When cables were improperly installed at a low depth, cities are now mandating that all cables be buried at the correct depth of 70 cm. This rework can cost 3-4 times the normal digging expenses. In total, this could impact around 40 km of cable installation, resulting in substantial financial burdens for contractors who failed to adhere to city guidelines. When cables are not installed according to specifications, the repercussions can include: Additionally, if two network cables are installed in the same trench and one is damaged or incorrectly placed, all consumers relying on those cables will experience interruptions in their network service. This could lead to significant dissatisfaction and loss of customer trust. The rework project could likely extend over a period of 4-6 months, further compounding the financial and reputational costs for the involved parties. This is where Fieldsight comes into play. With a subscription starting at just €500 per month, the benefits of using our product far outweigh the potential costs associated with cable cuts. In the screenshot above, you can see how our GIS software works: maps of existing utilities can be uploaded to easily spot intersections with your planned cable. This interface is also accessible on mobile. To ensure accurate trench depth, Fieldsight receivers can be equipped with a Depth Handle or Lidar, allowing workers on-site, as well as all stakeholders, to monitor and control the trench depth in real time. This added feature supports compliance with required specifications and minimizes the risk of costly rework. By providing real-time documentation and tracking of installed cables by enabling access to existing route information, Fieldsight helps construction companies: Minimize the risk of accidental cuts by having detailed maps at your fingertips Prevent incidents that could lead to significant repair expenses Limit the need for extensive excavation and the manpower required for repairs Maintain trust with clients and stakeholders by demonstrating proactive risk management Our turn-key solution is designed for ease of use, requiring no special training to operate. Additionally, users can upload municipal maps that indicate previously installed cables, helping to visualize potential hazards and minimize risks. In conclusion, investing in a Fieldsight subscription not only enhances operational efficiency but also provides a robust safeguard against the unpredictable costs of fiber cable damage and misinstallation, making it a wise financial decision for construction companies.Financial Impact of Cable Damage

Construction Quality Issue: Insufficient Cable Laying Depth Leads to Costly Rework

Fieldsight’s Preventive Solution

Avoid Costly Mistakes

Reduce Repair Costs

Save Time and Resources

Protect Your Reputation

Learn more about our software

Book a demo